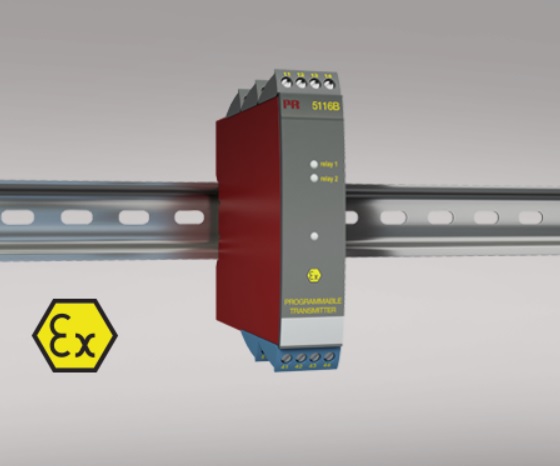

Programmable transmitter

Input for RTD, TC, mV, Ohm, potentiometer, mA and V

2-wire supply > 16.5 V to Ex zone 0

Bipolar voltage input

Output for current, voltage and 2 relays

Universal supply by AC or DC

Application

Linearized, electronic temperature measurement with RTD or TC sensor.

Conversion of linear resistance variation to a standard analog current / voltage signal, i.e. from solenoids and butterfly valves or linear movements with attached potentiometer.

Power supply and signal isolator for 2-wire transmitters.

Process control with 2 potential-free relay contacts which can be configured for advanced functions.

Galvanic separation of analog signals and measurement of floating signals.

Technical characteristics

Within a few seconds the user can program PR5116B to suit the specific application.

By way of the front push-button the input can be calibrated to the exact span of the process. Zero drift on the process signal can be adjusted by a single press of the front buttton.

A green front LED indicates normal operation and malfunction. A yellow LED is ON for each active output relay.

Continuous check of vital stored data for safety reasons.

3-port 3.75 kVAC galvanic isolation.

Mounting / installation

Mounted vertically or horizontally on a DIN rail. As the devices can be mounted without any distance between neighboring units, up to 42 devices can be mounted per meter.

Input for RTD, TC, mV, Ohm, potentiometer, mA and V

2-wire supply > 16.5 V to Ex zone 0

Bipolar voltage input

Output for current, voltage and 2 relays

Universal supply by AC or DC

Application

Linearized, electronic temperature measurement with RTD or TC sensor.

Conversion of linear resistance variation to a standard analog current / voltage signal, i.e. from solenoids and butterfly valves or linear movements with attached potentiometer.

Power supply and signal isolator for 2-wire transmitters.

Process control with 2 potential-free relay contacts which can be configured for advanced functions.

Galvanic separation of analog signals and measurement of floating signals.

Technical characteristics

Within a few seconds the user can program PR5116B to suit the specific application.

By way of the front push-button the input can be calibrated to the exact span of the process. Zero drift on the process signal can be adjusted by a single press of the front buttton.

A green front LED indicates normal operation and malfunction. A yellow LED is ON for each active output relay.

Continuous check of vital stored data for safety reasons.

3-port 3.75 kVAC galvanic isolation.

Mounting / installation

Mounted vertically or horizontally on a DIN rail. As the devices can be mounted without any distance between neighboring units, up to 42 devices can be mounted per meter.